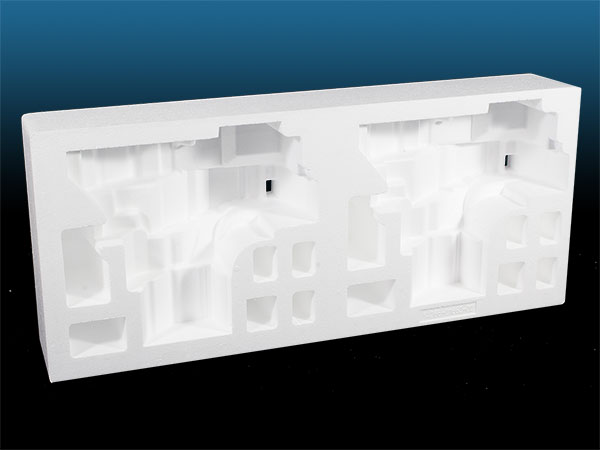

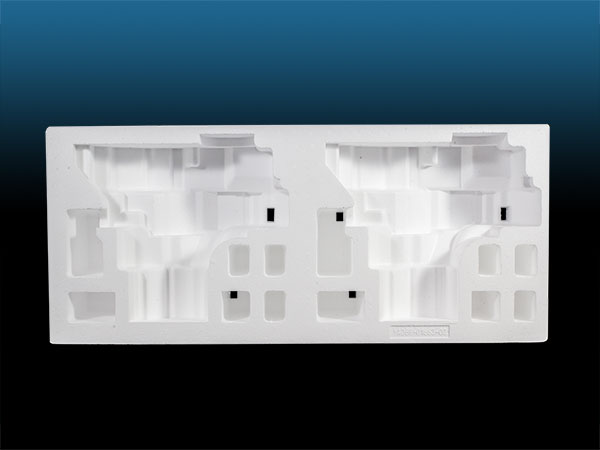

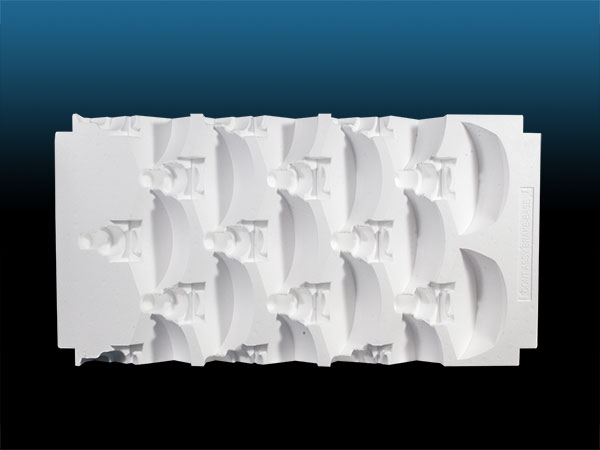

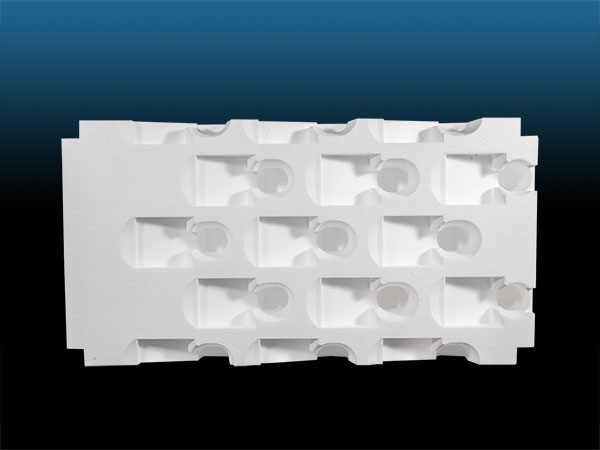

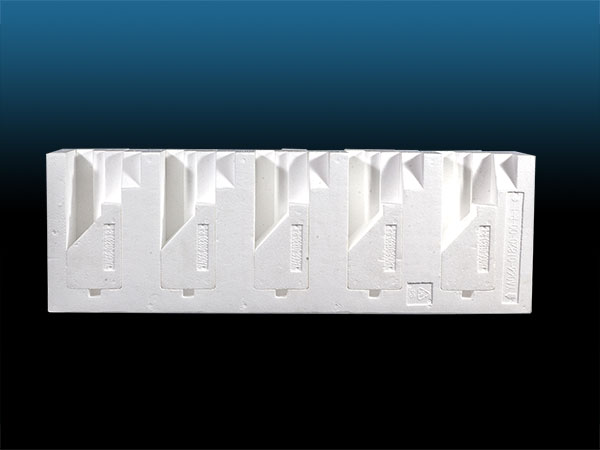

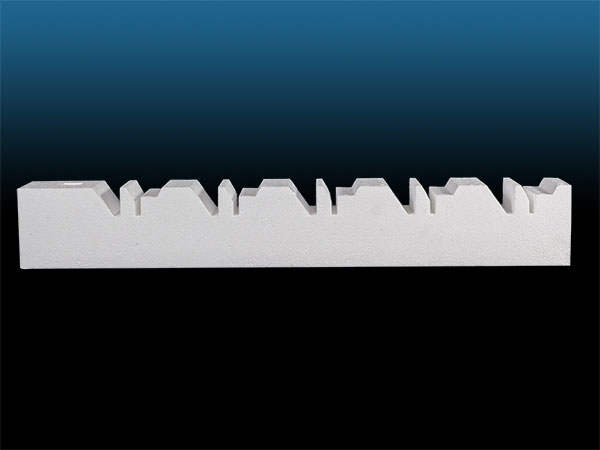

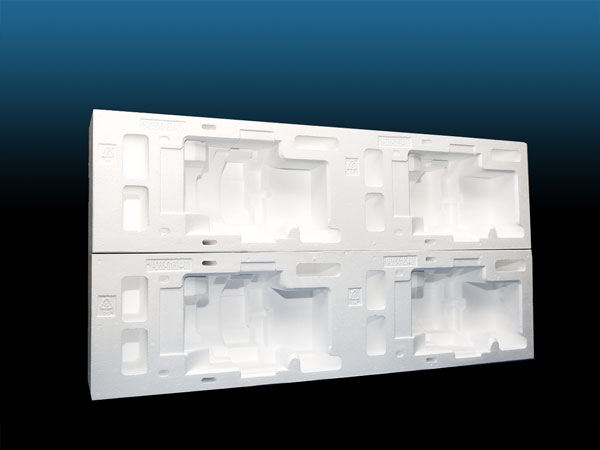

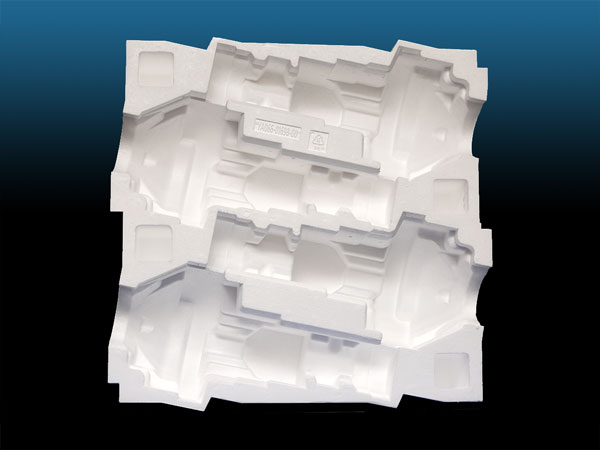

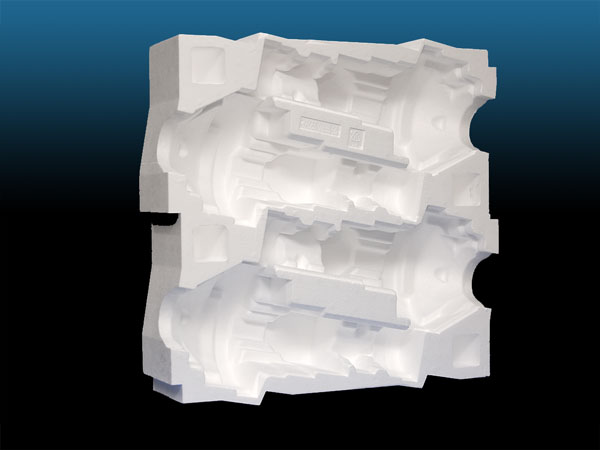

EPS FOAM

Expanded Polystyrene (EPS) is a white foam plastic material produced from solid beads of polystyrene. It is a closed cell, rigid foam material produced from Styrene which forms the cellular structure and Pentane which is used as a blowing agent.

EPS Foam is very lightweight and offers very low thermal conductivity, low moisture absorption and excellent cushioning properties.

The key benefits of using EPS Foam:

- Energy efficiency and saving

- Thermal resistance and insulation

- Chemical inertness

- Cost-effectiveness

- Excellent impact strength & Dimension stability

- Recyclable

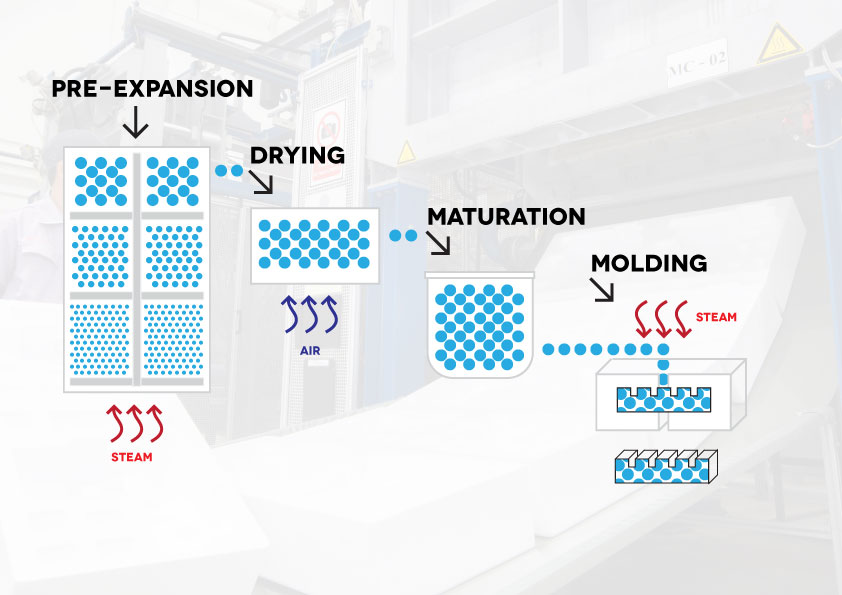

Expansion Process

EPS Expansion Process Expansion Process There are 3 expansion processes in EPS.- Pre-expansion

- Ageing

- Forming (Molding)

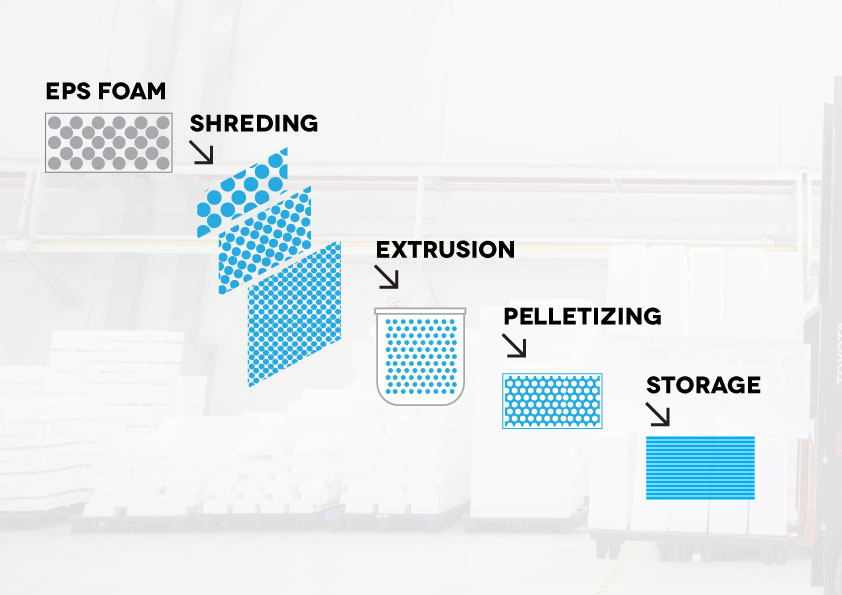

Recycling Polystyrene Using a Pelletizing Machine

How to recycle EPS with extrusion pelletizing machine- The waste is broken down into small pieces of EPS foam by a crusher.

- The EPS fragments are melted and passed through a plastic extruder.

- The melted EPS flows out of the small outlet of the extruder and solidifies into a continuous thin line of solid plastic.

- The plastic then passes through a cooling bath and is then cut into small pieces.

- This plastic can then be used for the production of plastic products such as picture frames and household pots.